Driveways are one of the critical features that would enhance your property. A functional and durable path would add beauty to your property. However, achieving a durable resin driveway surfacing involves selecting a suitable base. Certain sub-surfaces are not appropriate for a resin-based surfacing. If you have been confused about what type of support is right for your resin bound driveways, we will help you clarify the differences and identify the different bases for resin drives.

What Are Resin Driveways

Resin driveways are driveways where a resin coat is applied to a suitable base material. It is an excellent way to protect your driveway and has a lot of other advantages. The overall result of using resin is a hard surface that is resistant to weed and requires low maintenance.

Resin Bond Driveways vs Resin Bound Driveways

While both driveways seem similar, there is one significant difference between them. Resin bond driveways have aggregates spread unto the resin surface. If the aggregate used is stone, the driveway is a resin bonded stone driveway. Also, you might prefer a bonded gravel driveway; this involved using gravel as your resin aggregates.

In contrast to a resin bond driveway, resin bound driveways use a pre-mixed of aggregate and resin substance. Bonded gravel driveways are not porous, but resin bound gravel driveways are permeable. The other difference include

- Resin bond surfacing is one of fine aggregate while resin bound surfacing is one of mixed aggregate( resin and a binder)

- A single layer of resin bond driveway is usually 3-6mm thick while resin bound driveway is 15-40mm thick

- Resin bond surfaces are impermeable while resin bound surfaces are permeable

- There is a limited choice of aggregate for resin bond driveways. While resin bound driveways have a variety of choice to select.

Types Of Resins Used For A Resin Bound Driveways

Resin bound driveways use polyurethane resin with thickness ranging from 15mm-20mm. There are two types of polyurethane resin. One is ultraviolet accommodating and stable while the other is not. The aliphatic polyurethane remains the same after exposure to sunlight while the aromatic polyurethane will turn yellow or darken after exposure to sunlight. Therefore, you should select your resin based on what you desire.

Ideally, the UV stable resin is right if you want to retain the colour of your driveway. Colour plays a significant role in the beauty of the home. Also, ultraviolet degradation is not associated with colour alone, the surfaces could become dull, and the driveway loses its function. However, aromatic polyurethane is ideal in cases where there is low to mild exposure to sunlight.

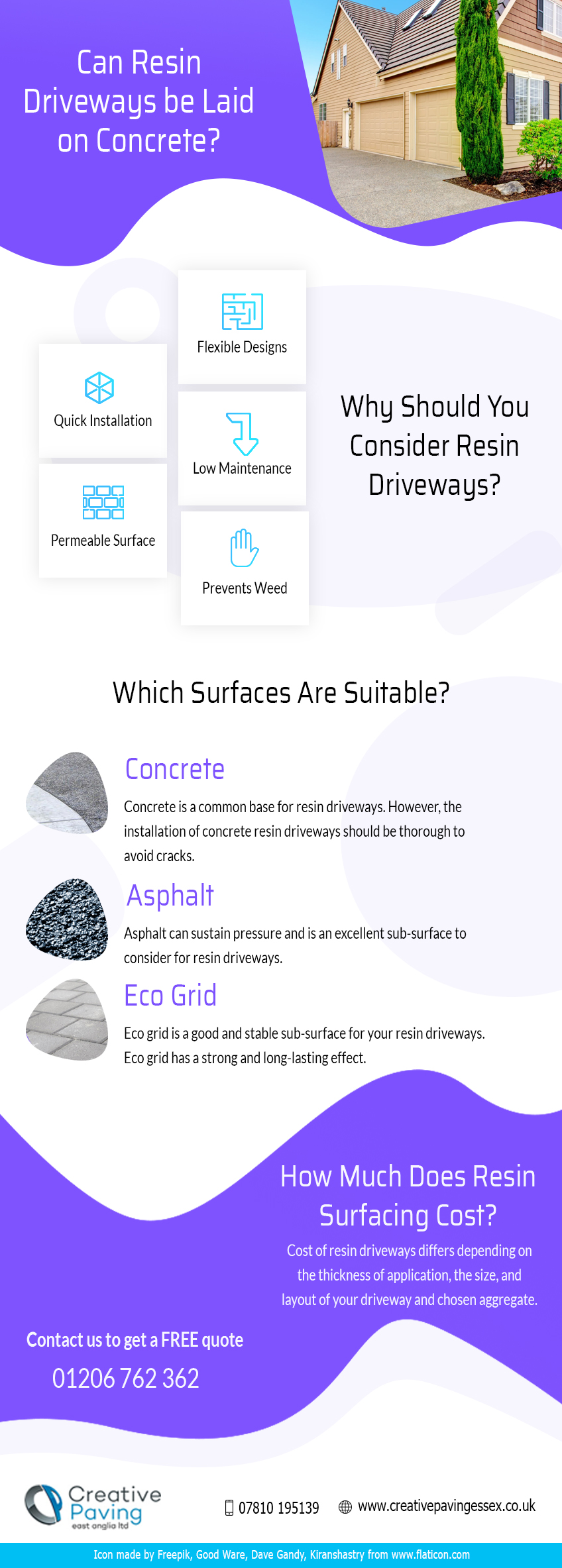

Why Should You Consider Installing A Resin Bound Driveway?

Resin bound driveways have many advantages. Conventional surfaces are impermeable which could increase the risk of flooding. Permeable resin bound gravel would help to prevent this problem. Also, Resin bound driveways are a smart choice nowadays. When your contractor installs a resin driveway very well, it is a superb paving system. They provide excellent slip resistance, especially in cold seasons. Other benefits of resin-driveways include:

Quick Installation

Resin bound driveways installation could take a few days. However, weather conditions could affect the installation, and it might take up to a week. Installation is even faster if there is an existing base such as concrete.

Permeable Surface

Resin bound driveways often make use of permeable resin bound gravel. As a result, water will go through the resin neatly without damaging the pavement. High permeability makes resin driveway a great option. If the installation is done correctly, it should not cause drainage issues.

Flexible Designs

Resin bound driveways are famous for their appealing and great designs. They add beauty to the home. There are a variety of colours and designs that you could choose. Also, you could combine designs for a more enhanced look and achieve a visual contrast. There is a limitless choice of blends and combinations.

Low Maintenance

Resin driveways require little maintenance. Maintenance is not as frequent in comparison with other types of driveway surfacing.

Prevents Weed

Certainly uprooting weed every time from your driveways could be annoying. Thanks to resin driveways, you do not have to face this problem anymore.

Problems Associated With The Maintenance Of Resin Driveways

While resin driveways seem to be the best option, specific issues could arise. These problems are often due to wrong bases, improper installation or the quality and type of resin used. Most of these problems are associated with inexperienced contractors. Contractors should be experienced, licensed and certified to install resin driveways. Your contractor should be knowledgeable enough to help you in your decision making and selection of your resin base and aggregate.

While concrete resin driveways are perfect, there are other suitable bases. It is essential to refrain from using a corrupt and old concrete pavement for your resin driveway. The result is structural damage. Structural problems in resin driveways include thinning of the resin, absorption of resin by a wet concrete slab, major cracks. Remember, you can avoid these problems if you hire the right contractor.

The Surfaces Suitable As A Base For Resin Application

Every resin bound driveway requires a sub-surface which serves the base. The subsurface could be an existing surface like concrete or asphalt. Also, it can be a newly laid base. Although each base has certain advantages, concrete and asphalt are standard. The popularity is because they are monolithic – they are whole pavements with single slabs and few joints. The other types of pavements known as the elemental pavements and could cause cracks and ruin the appearance of the resin driveway.

Whichever base you select, it is vital to hire a professional. Resin sets in quickly usually within 60-70minutes. Therefore, ensuring that the resin and aggregate are applied, spread and levelled up evenly is vital.

Concrete

Most paths already have concrete as the initial driveway pavements. As a result, Concrete is a common base for resin driveways. However, the installation of concrete resin driveways should be thorough to avoid cracks. Existing concrete must be assessed and found suitable before use. Also, ensure that your contractor makes use of primers in the installation of your concrete resin driveway.

Primers are substances that would help your resin and concrete adhere to each other. A polymer-based primer is ideal for concrete resin driveways. However, the application should not be on a wet concrete slab. Concrete must be allowed to dry properly to prevent damage of resin caused by moisture vapour pressure. It is advisable to wait for three weeks before application of resin in warmer seasons and longer in cold seasons. Applying resin on a dry concrete pavement helps to prevent wasting your resin material. Generally, concrete resin driveways provide a porous and durable path for areas with traffic.

Asphalt

Like concrete, Asphalt is a common base for resin driveways. Asphalt can sustain pressure and is an excellent sub-surface to consider. Asphalt could easily maintain the structural integrity of your driveway.

Eco Grid

Eco grid is a good and stable sub-surface for your resin driveways. Eco grid has a strong and long-lasting effect. Also, it is quick and easy to install. The interlocking network enables your driveway to withstand high pressure, and it allows water permeability. However, the application of eco-grid sub-base can be costly. You would need double the amount of resin to cover it.

Things To Check For When Using An Existing Base

It is very crucial to assess your existing base. Possibly, you have an old concrete pavement, and you decide to use it. It would save you the cost of getting a new base. However, failure to check your base would cost more money later as you would need to reapply your resin.

Check if a base is in the right condition and look for the following

- Major cracks

- Potholes

- Weeds

- Porosity

Finally, the cleaning of an old base is vital. You should remove any debris, dirt or organic material. All of this would ensure you get a durable resin driveway.

How Much Does Resin Surfacing Cost?

It is easy to neglect the fact that you need an outstanding driveway. Especially when you think about the cost of resin and contractors. However, you could achieve a durable resin bound surface within your budget. Cost of resin driveways differs depending on the thickness of application, the size, and layout of your driveway and chosen aggregate. Also, the contractor you choose determines how much you spend. Cheaper contractors do not necessarily give you the best.

How Long A Resin Will Bound Driveway Last

Resin bound driveways could last for a long time. Although you need to consider other factors like the type of base, type of resin used and the contractor you hired. On average, your resin driveway should last 15-20 years if you maintain it properly. The resin-based surfacing is a proper surfacing for your driveways among other things. Also, a good base would make your driveway last longer and work efficiently. In a correct and perfect instance, your resin bound driveway would be laid by professional and experienced contractors using a quality UV resistant resin on a suitable and robust base.

In conclusion, the resin-based surfacing is selective of sub-surfaces you could use. Although resin driveways are durable and efficient, the wrong base could cause problems eventually. At creative paving, we have professionals that are experienced and certified. They would help to assess your sub-surface and carefully install your new resin driveway.